Welcome to Qingdao sisa abrasives Co.,Ltd. website Tel:+86-17860727630

- Home

- Mobile website

Mobile website

Mobile website

- Contact

Mobile website

Mobile website

Th e products cover the whole valve grinding process, such as valve lock clamping groove grinding, valve stem centerless grinding, valve cone grinding, valve base cylindrical grinding and valve end face grinding, etc.

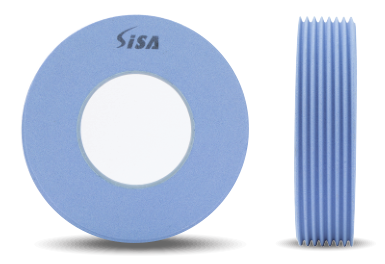

The products are mainly used for grinding crankshafts and camshafts for engines in automobile, agricultural vehicle and marine industry. Th e group crankshaft grinding wheel has good dimensional consistency, can realize synchronous dressing, synchronous feeding and synchronous grinding, and has good shape retention of the crankshaft journal.

Products include wormshaft grinding, forming grinding, generating grinding and other gear grinding, double bevel and disc grinding wheels. It can be designed and manufactured according to customer requirements. Th e static balance of the grinding wheel is more than 30% better than the national standard. It is suitable for all kinds of domestic and imported gear grinding machines. Wormshaft grinding wheel can process gear with single head, multiple heads, various modules and pressure angles.

It is made of BCA-F ceramic abrasive which is newly developed by our company. It is mainly used for grinding wormshaft.The maximum speed is 80m/s.The gear is not burned and has good shape retention and high grinding precision and longer service life.

Th e products cover the whole bearing grinding process, such as centerless grinding and end face grinding of bearing rings and rollers, channel grinding of inner and outer rings of bearings, inner circular grinding of bearings, etc. For example, the grinding wheel of the outer groove of the bearing inner ring is mainly grinded by cutting in method, which has the characteristics of high working speed, good roughness of the workpiece, good shape accuracy retention of the bearing roller and groov..

Th e products are used for high-precision grinding of corrugated rollers for various packaging machinery.Th e grinding wheel has the characteristics of loose structure, uniform hardness, large cutting depth, high e ciency, good chip removal and heat dissipation, no burn and good shape retention.

Centerless grinding is the grinding of the uncertain rotation center of the workpiece,which is composed of grinding wheel, guide wheel and workpiece support (support plate). During grinding, the workpiece is supported by the supporting plate and rotates at high speed between the grinding wheel and the guide wheel for grinding. It is widely used for grinding cylindrical surface, conical surface and innerand outer surface of rotary body.