Welcome to Qingdao sisa abrasives Co.,Ltd. website Tel:+86-17860727630

- Home

- Mobile website

Mobile website

Mobile website

- Contact

Mobile website

Mobile website

BCA-M is the ceramic alumina abrasive mircro-powder developed and produced by SISA.It's a composition of sub-micron aluminum oxide and lamellar grain containing rare earth materials. The graincombines unique self-sharpening properties with a high hardness and toughness. BCA-M is applied to kinds ofbonded and coated abrasive tools. BCA-Mcan be used in a wide range of applications and provides highestperformance and a long tool life.

CA-Z is a ceramic abrasive containing zirconium, which has the characteristics of high hardness, high wear resistance, excellent toughness, good self sharpening, high grinding efficiency, excellent machining surface quality, and wide applicability in the field of grinding processing.

CA-EX is a zirconium containing ceramic corundum abrasive prepared by a special crushing method. Its particle shape and properties have unique advantages, with extremely low packing density, sharp cutting edges, and high hardness. It can efficiently cut into workpieces, reduce friction resistance, and is particularly suitable for processing high hardness, high-strength materials, and thermal sensitive materials.

CA-PL is a plate-shaped ceramic corundum abrasive, which has the characteristics of sharp grinding and low heat generation in workpiece grinding.

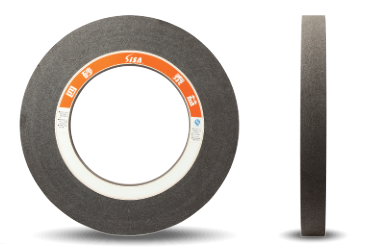

It is made of BCA-S ceramic abrasive which is newly developed by our company. It is mainly used for grinding high-end roller. It has strong cutting force, good self sharpening, small load, and the grinding ratio is more than 2 times that of ordinary roller grinding wheel.

With unique manufacturing technology, the product has stable hardness, uniform structure, good balance performance, small grinding resistance, unfit burn of workpiece, high grinding efficiency and good processing accuracy consistency.

Th e products cover the whole valve grinding process, such as valve lock clamping groove grinding, valve stem centerless grinding, valve cone grinding, valve base cylindrical grinding and valve end face grinding, etc.